Mechanical malfunctions

Damage to mechanical equipment can be caused by design or manufacturing defects, misuse, material degradation due to use in severe conditions or even a lack of maintenance.

Our scope

Air Liquide CTE conducts investigations to determine the causes of the damage.

We carry out these investigations after component failures, observation of cracks, or any other failure of mechanical parts.

What are the risks associated with mechanical failures ?

Defective equipment or accessories can cause dangerous situations (gas or liquid leakage, explosion, etc.) for users.

What are the consequences ? Asphyxiation, burns or injuries.

Which equipment can we analyse at CTE ?

Damaged materials and components, after accident or incident :

- After leaks, ruptures, cracks, etc.

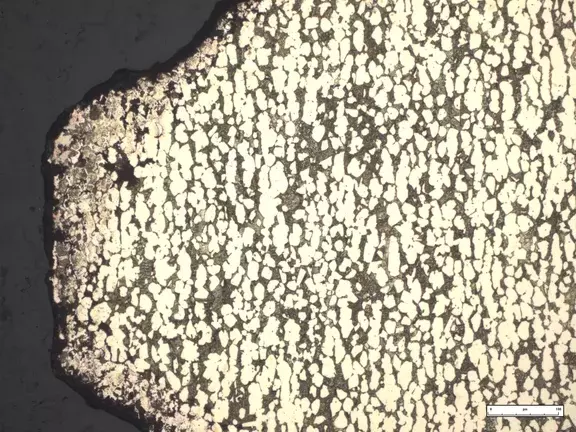

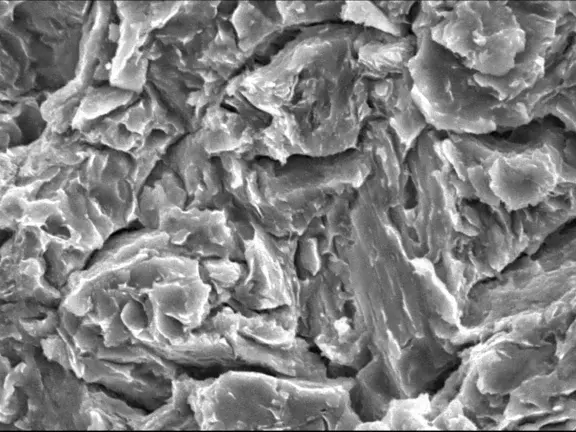

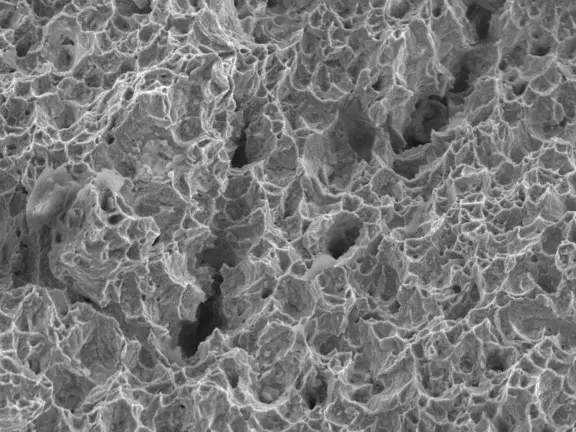

- Analysis of metallurgical defects.

- Identification of technical causes.

The following equipment :

- Valves, hoses, regulators, fittings.

- Gas cylinders, tubes, cryogenic containers.

- Welded components.

What are the most common damage mechanisms seen ?

Our testing activities

CTE offers tests on oxygen safety, cylinder conformity and equipment performance.

Contact CTE

AIR LIQUIDE Global E&C Solutions France - CTE

Campus Innovation Paris 1

Chemin de la Porte des Loges

78350 LES LOGES EN JOSAS

01 39 07 62 62