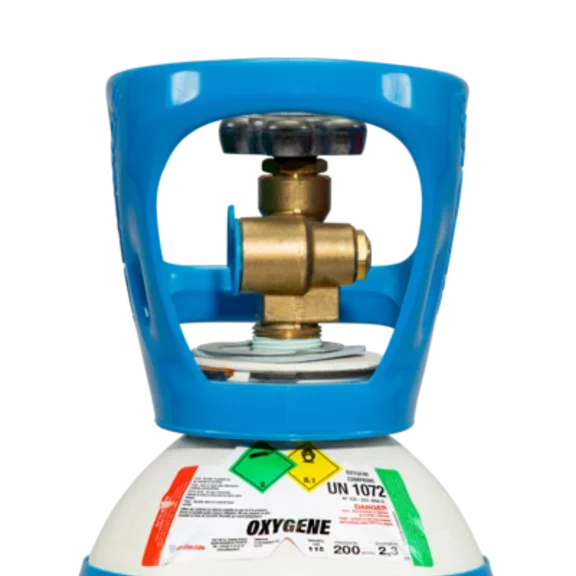

Valves and other accessories

These tests consist in demonstrating the ability of valves and other equipment (non-return valves, pressure regulators, safety valves, etc.) to withstand their normal operating conditions.

Why test the performance of valves and fittings?

Whether used frequently or periodically, this equipment can cause gas or liquid leaks and become projectiles.

What are the objectives? Ensuring user safety and equipment performance over the long term.

What tests are performed on valves and accessories ?

Our technicians can perform the following tests :

- Endurance tests

- Helium leak tests

- Proof tests

- Excessive torque tests

- Flame impingement test

- Flow measurements

Most of the tests are carried out in accordance with ISO 10297 and ISO 15996 standards.

We also test the cylinder valve guards

Air Liquide CTE performs the following tests according to standard 11117 :

- Torsion/axial torque tests

- Cylinder drop tests to verify the protection provided by the valve guard

These tests may be conducted :

- At room temperature and down to -20°C

- Up to 2.1 m

We can film drop tests using high-speed cameras.

Our failure analysis activities

Oxygen failures, mechanical failures, lifetime of methane steam reformer tubes, etc.

Contact CTE

AIR LIQUIDE Global E&C Solutions France - CTE

Campus Innovation Paris 1

Chemin de la Porte des Loges

78350 LES LOGES EN JOSAS

01 39 07 62 62